Business

Understanding Atex Restoration: A Guide to Industrial Safety

Industrial environments are often fraught with hidden dangers. Beyond the obvious heavy machinery and high voltages, there are invisible threats that pose catastrophic risks: combustible dust, flammable gases, and volatile vapors. In these volatile atmospheres, a single spark can lead to disaster. This is where the concept of ATEX comes into play, and why maintaining equipment through Atex Restoration is not just a maintenance task—it is a critical safety imperative.

For facility managers and business owners operating in hazardous environments, understanding the lifecycle of their equipment is vital. Over time, fans, motors, and pumps degrade. In a standard factory, a failing bearing might just mean a machine stops working. In an explosive atmosphere, a failing bearing can generate the heat or spark necessary to ignite a blast.

Atex restoration is the specialized process of inspecting, cleaning, repairing, and recertifying equipment to ensure it remains safe for use in these hazardous zones. Rather than costly replacements, restoration offers a pathway to extend the life of your assets while ensuring full compliance with stringent safety directives.

Decoding the Terminology: What is ATEX?

To understand restoration, we must first understand the standard. “ATEX” is an abbreviation derived from the French title of the European Directive 99/92/EC: Appareils destinés à être utilisés en ATmosphères EXplosibles (Equipment intended for use in explosive atmospheres).

While it originates in Europe, the principles of ATEX are recognized globally as a benchmark for safety. The directives consist of two main parts:

- Directives for the Employer: Focusing on the minimum requirements for improving the safety and health protection of workers potentially at risk from explosive atmospheres.

- Directives for the Manufacturer: Concerning the equipment and protective systems intended for use in these potentially explosive atmospheres.

Equipment certified as “ATEX compliant” is designed to eliminate ignition sources. This includes ensuring surfaces don’t get too hot, sparks aren’t generated during operation, and static electricity is properly discharged.

The Critical Importance of Atex Restoration

Over time, even the highest quality industrial equipment suffers from wear and tear. Corrosion, dust accumulation, and mechanical fatigue can compromise the specific safety features that made a machine ATEX compliant in the first place.

The Risk of Neglect

Neglecting this equipment doesn’t just lower efficiency; it invites tragedy. A specialized extraction fan in a chemical plant, for example, is designed to prevent sparks. If the impeller becomes unbalanced due to grime buildup, it may wobble and strike the casing. In a non-hazardous area, this is a noise nuisance. In an ATEX zone filled with chemical vapors, that metal-on-metal contact creates a spark that acts as an ignition source.

Compliance and Liability

Regulatory bodies take explosive atmospheres seriously. If an incident occurs and it is discovered that equipment was poorly maintained or no longer meets the safety standards it was certified for, the liability falls squarely on the business owners and operators. Atex restoration provides a paper trail of due diligence, proving that equipment has been professionally maintained to the required standard.

The Restoration Process: Step-by-Step

Restoring equipment for hazardous areas is not a job for a general handyman. It requires specialized knowledge of hazardous area classification and mechanical engineering. Here is what the typical Atex restoration process looks like.

1. Detailed Inspection and Assessment

The process begins with a rigorous audit. Technicians examine the equipment to identify the specific ATEX rating (e.g., Zone 1, Zone 2, Zone 21, or Zone 22). They assess the physical condition of the unit, looking for corrosion, bearing wear, seal integrity, and any modifications that might have been made since installation.

2. Decontamination and Cleaning

Before any mechanical work can begin, the unit must be cleaned. In industries like food processing or woodworking, layers of combustible dust can accumulate on motors and fans. This layer acts as insulation, causing the equipment to run hotter than its “T-rating” (temperature class) allows. Restoration involves stripping away these contaminants without damaging the underlying components.

3. Mechanical Repair and Replacement

This is the core of the restoration. Worn components are replaced, but not with generic parts. Every screw, seal, and bearing used must meet the original equipment manufacturer (OEM) specifications or better to maintain the safety integrity.

- Bearings: Replaced to ensure smooth, friction-free rotation.

- Impellers: Re-balanced to prevent vibration and casing contact.

- Seals: Checked and replaced to prevent ingress of dust or gas into electrical components.

4. Re-Coating and Finishing

Corrosion is the enemy of ATEX equipment. During restoration, casings are often bead-blasted and re-coated with specialized anti-static or corrosion-resistant paints. This ensures that the equipment can withstand the harsh environment it operates in, preventing future degradation.

5. Testing and Documentation

Once reassembled, the equipment undergoes rigorous testing. This includes vibration analysis and temperature monitoring. Finally, the service provider issues documentation certifying that the unit has been restored to a safe operating condition compliant with relevant standards.

Industries That Rely on Atex Services

You might be surprised by how many industries operate within explosive atmospheres. It is not limited to oil rigs.

- Food and Beverage: Flour, sugar, and starch dust are highly explosive. Bakeries and grain silos require rigorous Atex restoration for their conveyors and extraction systems.

- Pharmaceuticals: The handling of powders and solvents during drug manufacturing creates hazardous zones requiring specialized air handling units.

- Woodworking and Paper: Sawdust and paper fibers are significant combustion hazards.

- Automotive and Paint: Spray booths generate flammable mists and vapors, requiring spark-proof ventilation systems.

- Waste Management: Decomposition in landfills and sewage treatment plants produces methane gas, necessitating explosion-proof pumps and monitoring gear.

Restoration vs. Replacement: The Economic Case

When a critical piece of ATEX machinery fails or degrades, the knee-jerk reaction is often to replace it. However, new ATEX-certified equipment is significantly more expensive than standard industrial machinery due to the engineering and certification costs involved.

Atex restoration offers a sustainable and cost-effective alternative.

- Cost Savings: Restoration can cost a fraction of the price of a new unit, often saving businesses 50% to 70% of the capital expenditure.

- Reduced Downtime: Sourcing a specific, custom-built ATEX fan or motor can take weeks or months due to supply chain complexities. Restoration can often be completed in days.

- Sustainability: Repairing and reusing heavy machinery reduces industrial waste and the carbon footprint associated with manufacturing new units.

Frequently Asked Questions

Is Atex restoration a legal requirement?

While “restoration” itself isn’t the specific legal term, maintaining equipment in a safe condition is a legal requirement under workplace safety laws (like OSHA in the US or DSEAR in the UK/EU). If equipment degrades to the point where it is no longer safe, you are non-compliant. Restoration is the method used to achieve compliance.

Can my regular maintenance team perform Atex repairs?

Generally, no. Unless your internal team has specific training and certification in hazardous area equipment repair (such as IECEx or CompEx training), they should not attempt to repair ATEX equipment. Improper reassembly can void the safety rating and create invisible hazards.

How often should equipment undergo restoration?

This depends on the severity of the environment and the “Zone” classification. Harsh environments with corrosive chemicals may require annual checks and restoration, while cleaner environments may allow for longer intervals. Consult the manufacturer’s guidelines and your risk assessment data.

Prioritizing Safety and Longevity

Atex Restoration plays a critical role in industrial safety, which is never a passive activity and always demands vigilance and proactive management. Equipment operating in explosive atmospheres serves as the first line of defense against potential catastrophe. Through professional restoration and compliance-focused maintenance, businesses safeguard their most valuable assets—their employees—while also making a sound financial decision. This approach bridges the gap between operational efficiency and strict safety compliance, allowing production to continue smoothly without compromising security.

If your facility operates within hazardous zones, take the time to audit your machinery today. A proactive approach to restoration is always less costly than a reactive approach to disaster.

Business

Tips to Avoid Parking Fines in NYC

Parking in New York City can be challenging, given the dense traffic, fluctuating restrictions, and strict enforcement policies. With NYC’s stringent parking rules, even the most experienced drivers may encounter unintentional violations. Understanding common rules and best practices, along with using reserved spaces, helps reduce avoidable penalties. Here are some tips to avoid fines and make parking in NYC more manageable:

Pay Attention To Parking Signs

NYC streets and parking structures are filled with many different signs, each outlining different rules and restrictions regarding where you can or cannot park. These include signs that indicate:

- No Parking

- No Stopping

- Loading Zones

- No Standing.

Some signs are complex, and they contain more than one rule in a single post. These rules may also be tied to a specific day or time. Misreading these signs or overlooking a restriction sometimes results in a violation, leading to penalties.

Alternative side parking (ASP) signs are one type that can easily be misunderstood. ASP rules dictate when vehicles should be moved to allow for street cleaning. The enforcement of these rules varies by day, time, and location. Multiple ASP schedules sometimes apply to different sides of the same street, which can make the signs confusing.

Confirm the street cleaning schedule before leaving your vehicle to avoid fines or unnecessary trips back to move your car. If the signs seem unclear or contradictory, it may be safer to find another spot rather than risk misinterpreting the rules. Parking garages also offer a reliable alternative. They often have clearly defined rules, and they keep your vehicle off the street. This provides protection from street-cleaning restrictions.

Keep Track of Time Limits

When using metered parking, keep track of the meter’s time limit and payment status. Most metered spaces enforce strict rules, and failing to pay or letting the meter expire tends to result in violations. Some locations impose strict maximum parking durations that prevent car owners from extending their time beyond a certain limit, even if the meter is paid. For such spaces, you can set a reminder on your mobile phone a few minutes before your meter expires. This gives you time to return and move your vehicle before traffic agents start imposing fines.

In some locations, including garages and privately managed parking facilities, you may find systems that allow remote time extensions through mobile apps or automated kiosks. This option lets you extend your time up to a specified limit without returning to your vehicle. Before leaving your car, review posted instructions or signage to confirm whether time extensions are permitted. If a payment machine is not working or does not accept payment, choose another space or facility to avoid potential violations and disputes.

Follow Proper Parking Guidelines

Using designated parking spaces helps prevent significant fines, and it avoids blocking traffic or access points. Avoid double parking by making sure your vehicle remains fully within marked spaces. Stay clear of fire hydrants, crosswalks, bus stops, and bike lanes. Improper parking can result in tickets, and it creates potential safety hazards for pedestrians and other drivers. Paying attention to curb markings also enables you to avoid unnecessary fines. In some areas of NYC, curb colors indicate specific vehicle restrictions. Red curbs typically mean no stopping, while blue curbs designate accessible parking spaces. Recognizing these visual cues can help you avoid restricted zones, even when signage is limited.

Reserve a Space in Advance

Some apps and websites allow you to reserve parking spaces in NYC ahead of time, typically in private garages or managed lots. Reserving in advance helps secure a legal and reliable place to park; this can reduce the risk of tickets. Pre-booking also minimizes the time spent searching for parking, especially during peak traffic hours.

Designated parking garages provide a monitored environment for leaving your vehicle for extended periods while you complete your activities in the city. Because garages vary in time limits and vehicle size restrictions, review each facility’s rules before reserving a space. Choosing garages that are conveniently located, well-lit, staffed, and secure can improve both safety and convenience. If you drive frequently in the city, joining a monthly program at a garage helps offer added value and flexibility.

Find Convenient Parking in NYC

Staying aware of parking rules is key to avoiding fines in NYC. While street parking may seem convenient, it comes with complex and strict regulations that vary by location, time, and day. Taking the time to understand posted signs and restrictions helps reduce unnecessary tickets; using garages and reserving spaces in advance is also beneficial. Contact a professional parking provider to secure a safe, legal, and reliable spot for your car.

Business

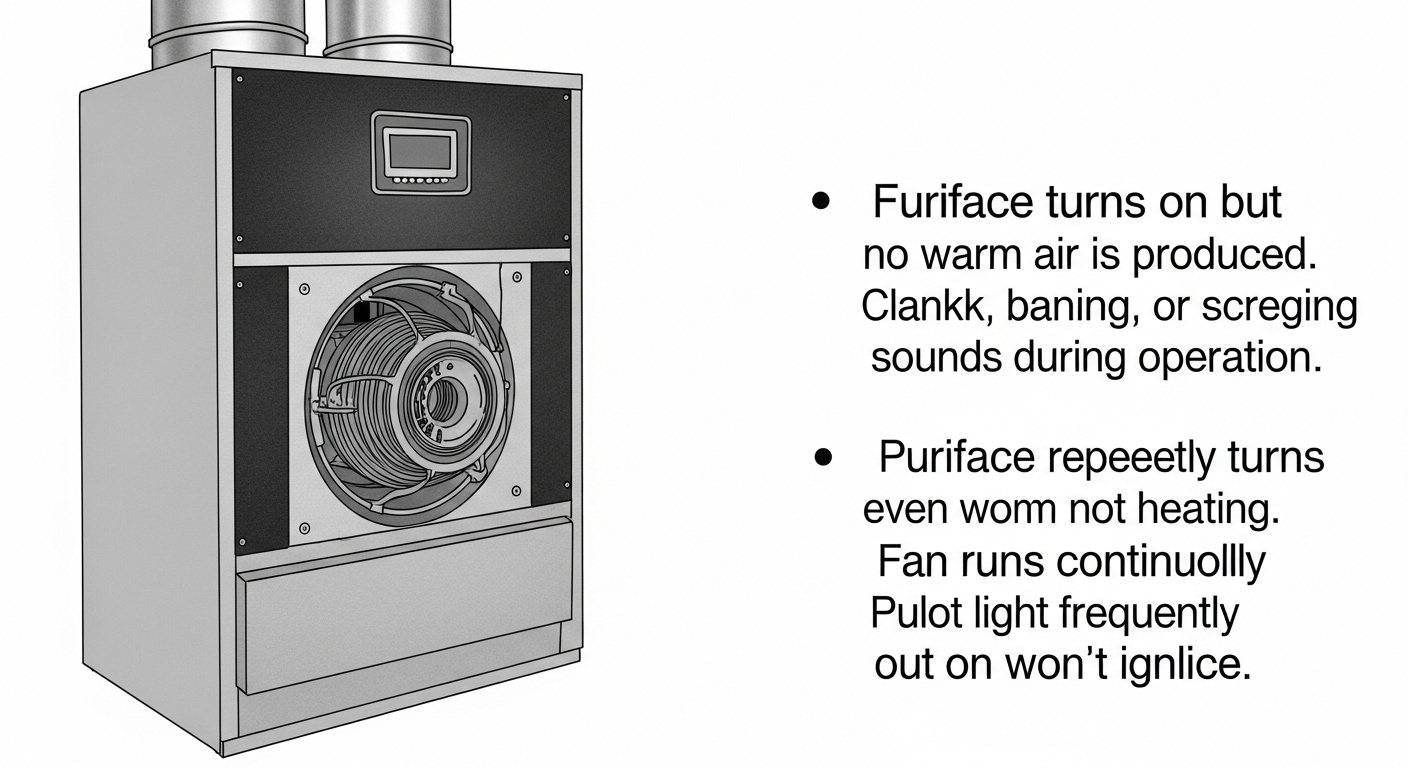

Common Issues That Require Furnace Repair

Qualified HVAC technicians can accurately identify and address furnace problems early on, preventing minor issues from escalating into major system failures. Repairs make sure your unit operates safely and at peak efficiency, and this promotes optimal heating throughout the year. Understanding the most common furnace problems helps you identify when it’s necessary to call a professional for assistance. Here are some common issues that require furnace repair:

Dirty or Clogged Air Filters

Air filters trap dust, pet dander, pollen, and other airborne particles, preventing them from entering the furnace’s internal components. Once the filters become dirty or clogged, they restrict airflow. This results in the system working harder to maintain efficient circulation of warm air throughout the house.

Reduced airflow can cause the furnace to overheat, triggering the limit controller, which shuts down the system as a safety measure. This problem creates a cycle where the furnace runs briefly, shuts down, and then restarts after it has cooled down. Filter replacement addresses minor issues, but professional repair can help assess other widespread related damages. Air filter repair improves heating efficiency and also promotes safe and reliable performance.

Faulty Thermostat

The thermostat serves as the command center of the furnace; it tells the system when to turn on or off to maintain the desired indoor temperature. When the thermostat is faulty, it sends incorrect signals to the furnace, resulting in inconsistent heating or no heat at all. A bad thermostat may also cause the system to cycle on and off frequently or shut down prematurely.

Thermostat malfunctions are sometimes triggered by dead batteries, calibration errors, faulty wiring, or older models that aren’t compatible with modern systems. Smart and programmable thermostats may experience another level of malfunctioning related to software glitches and programming issues. Professional furnace repair helps identify whether the problem lies within the thermostat itself or with its connection to the heating system. Addressing thermostat issues can restore efficient communication with the system, and this supports efficient temperature controls throughout the seasons.

Ignition Failure

The ignition system creates the flame that heats your home, and when it fails, you may be left in the cold. Modern furnaces use electronic ignition systems, while older gas models have pilot lights that must remain lit at all times. Signs of ignition failure include the pilot light constantly going out, intermittent heating, and burners clicking without lighting. Ignition problems pose potential safety risks because they involve gas and combustion. They require professional handling by qualified technicians. Failed ignition leaves the home without heat, but it can also strain other furnace elements as they repeatedly attempt to start the system.

Bad Heat Exchanger

A heat exchanger is the component that safely transfers heat from the flame and warms the air that is circulated in the house. It is responsible for separating combustion gases from the heated breathing air. A cracked or broken heat exchanger can allow cold air or combustion gases to escape into your house. When cold air leaks in, it disrupts heating, but when harmful gases such as carbon monoxide are released, they pose serious health and safety concerns.

Signs of a faulty heat exchanger include carbon monoxide alarms going off and strong, unpleasant odors. You may also notice soot buildup around your furnace and yellow or flickering burner flames. Heat exchanger problems are sometimes triggered by corrosion from combustion elements, chronic overheating, and poor maintenance. Professional furnace repair services help restore system performance and household safety.

Faulty Blower Motor

The blower motor is responsible for transferring heated air from the furnace into your home through the vents. If the motor fails, the furnace won’t efficiently distribute the heated air it creates; this makes it hard to maintain consistent indoor temperatures. When a blower motor fails, you may notice unusual whirring, rattling, or squealing noises. Some furnaces also continue to run without circulating warm air.

A faulty motor may add strain to other parts of the furnace and increase energy consumption as the system works harder to force air out. Possible causes of motor issues include general wear from prolonged use, worn-out bearings, overheating, and electrical problems. Professional repairs help evaluate whether the motor needs replacement or lubrication to restore reliable performance.

Hire a Professional Furnace Repair Company

Common furnace problems can increase energy consumption, reduce comfort, and pose serious health and safety risks. Professional furnace repair helps address these issues by restoring operational efficiency and reliability. Technicians may also identify hidden problems, such as cracked heat exchangers or faulty wiring, and this helps promote household safety. Hire a reliable furnace repair provider to explore solutions that meet your heating needs.

Business

What to Look For When Evaluating Your Bar Insurance Policy

Establishments such as bars and nightclubs are exposed to risks such as customer injuries on the premises, alcohol-related incidents, property damage, and more. The right bar insurance policy protects you against financial losses caused by these events by providing clear liability coverage. The policy should align with the bar’s daily operations and risk profile. When assessing your bar’s insurance needs, evaluate these factors:

Coverage Types

A broad coverage bar insurance policy, such as general liability, liquor liability, commercial property, and business interruption, helps make sure your bar is equipped to handle a variety of risks. Liability coverage protects your bar if someone is injured or their property is damaged on the premises. General liability specifically covers incidents such as slips, falls, or other accidents that may occur while guests are visiting.

Liquor liability protects you when overserved guests cause harm, whether through accidents or other incidents on your premises. Workers’ compensation covers injuries to staff, including burns or strains from lifting heavy objects in the bar. Commercial property insurance safeguards your inventory, furniture, and fixtures against risks like fire or theft of liquor stock. If a covered event forces your bar to close, business interruption coverage helps replace lost income. Equipment breakdown coverage is designed to protect necessary systems, such as refrigerators and draft lines, if they suddenly fail and disrupt service. Evaluate your business’s needs and risks before selecting a coverage type.

Policy Terms

Reviewing your insurance provisions carefully helps prevent claim denials caused by unclear rules or misaligned timelines. The policy period specifies the exact start and end dates of coverage, so it is necessary to make sure there is no gap between this policy and any prior coverage. Policies may be either claims-made or occurrence-based.

Claims-made policies cover only claims filed during the policy period, whereas occurrence-based policies cover incidents that happen during the policy period, regardless of when they are reported. Notice requirements often mandate prompt reporting of incidents to maintain uninterrupted coverage. Because some insurers impose strict deadlines, it is key to align policy timelines with your bar’s operations.

Endorsements and riders modify the original policy wording to add, restrict, or clarify coverage for specific exposures. Such exposures include hiring live entertainment or renting outdoor service areas. Review each endorsement carefully to determine the applicable limits and the conditions your bar must meet for a claim to be honored.

Policy Exclusions

Exclusions are specific situations or events that an insurance policy does not cover. Most bar insurance policies exclude intentional damage caused by owners or staff, normal wear and tear, failures in routine maintenance, and certain natural perils, such as floods, earthquakes, or mold. Some policies also limit or exclude assault and battery claims if inadequate security measures contributed to the incident, such as poor crowd control.

Insurers may restrict liquor liability coverage if alcohol is served without the proper licenses, to minors, or to visibly intoxicated patrons in violation of the law. Understanding these exclusions is necessary for identifying operational risks and implementing internal controls, including staff training and compliance procedures. By reviewing exclusions carefully, bar owners may reduce the chance of denied claims and verify that their risk management strategies align with the policy’s limitations.

Claims Processes

The claims process is a step policyholders follow to request payment from an insurance company after a covered loss. It describes how you report an incident and which channels you use. Examine how the insurer handles claims after they are reported, including having an adjuster assigned and evaluating liability and damages. Required documentation may include incident reports, photos, receipts, and proof of preventive measures, like staff training logs or equipment maintenance records.

Safety Standards

Some bar insurance policies include conditions or recommendations to reduce risk and support coverage. Start by reviewing security-related requirements, such as ID verification and operational surveillance cameras. Policies may also include alcohol-service expectations like responsible beverage service training and adherence to local liquor laws. If your bar’s policy includes employment practices liability, review the terms carefully, and confirm whether written harassment and discrimination policies are required.

Find the Right Bar Insurance Solutions

Professional bar insurance services provide coverage for liquor-related accidents, property damage, and employee-related risks. Experts identify any gaps in coverage and align your policy terms with alcohol service regulations and operational activities. Contact bar insurance specialists today to review your coverage options and get a suitable policy for your establishment.

-

Technology4 months ago

Technology4 months agoYourAssistantLive com: The Future of Smart Digital Assistance

-

food4 months ago

food4 months agoCalamariere: How to Perfectly Prepare at Home

-

Blog4 months ago

Blog4 months agoBaddi Hub: An Emerging Industrial and Business Hotspot

-

Blog4 months ago

Blog4 months agoSimpcit6: Redefining Simplicity in a Complex World

-

Health3 months ago

Health3 months agoNerovet AI Dentistry: Enhancing Patient Experience and Treatment Outcomes Dental Care

-

Technology3 months ago

Technology3 months agoVoomixi com: The Digital Platform Redefining Online Interaction

-

Crypto4 months ago

Crypto4 months agoCrypto30x.com vs Other Crypto Sites – Best Bitcoin Tools?

-

Lifestyle4 months ago

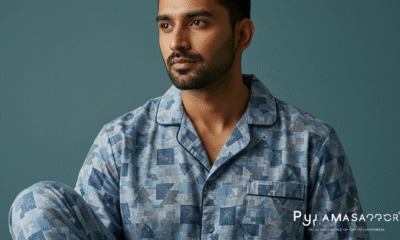

Lifestyle4 months agoPyjamaspapper: The Ultimate Blend of Comfort and Style in Sleepwear