Technology

How to Scale Your AI Development Team as Your Business Expands

Once only seen in labs and big tech firms, artificial intelligence now works quietly behind the scenes in many fields. Not just hospitals spotting illness or banks catching scams – also trucks finding faster routes, stores answering questions without people. Its presence grows, woven into daily operations far beyond early tests. With more companies relying on these smart systems, one problem stands out. Growing a team that builds such tools isn’t about speed alone – it must hold steady on care, fairness, and staying power.

A single study highlights firms using AI widely tend to see far better results financially – about three point four times higher gains compared to organizations stuck in small test phases. Getting there isn’t just about bringing on more coders; real progress leans on clear strategy, tight teamwork, solid leadership. In areas flooded with data, such as genomics, signs of change grow hard to ignore. The worldwide market for AI in this field moved from $0.4 billion in 2022 to $0.5 billion by 2024. Growth ahead looks steep – a projected rise at 32.3 percent each year until 2028 – with total value possibly hitting $2.0 billion when that span closes.

Start With a Clear AI Roadmap

Starting too big can trip up companies trying to grow their AI efforts. Without clear direction, adding more people rarely helps if priorities aren’t set first.

Before adding headcount, organizations should identify:

- Which business problems AI is expected to solve

- Whether solutions require machine learning, deep learning, or automation

- How success will be measured over time

Starting off, HBR.org points out how AI works best when it lines up with company goals instead of standing alone as a tech trial. When teams follow a clear plan, people who join later actually add useful results, not just scattered ideas.

Build Cross-Functional Teams, Not Silos

When AI gets trickier, it needs more than data scientists alone. Now, big AI groups often bring in software builders alongside ML experts. Product planners show up regularly too. Domain knowers add depth where needed. Data wranglers keep information flowing smoothly. Compliance checkers help avoid legal missteps along the way.

When it comes to creating reliable AI, teamwork across fields isn’t just helpful – it’s required. Take medical tools powered by artificial intelligence: they only work well when tech builders talk regularly with doctors. In banking, smart systems need input from legal experts early on – otherwise problems arise later. Accuracy, fairness, safety – all depend on who sits at the table during design.

When teams break out of isolation, progress speeds up. Working together early means fewer expensive fixes down the road.

Prioritize Data Infrastructure and MLOps

When an AI team starts growing but the data systems don’t keep up, things can fall apart quickly. More people mean more data, more manual setups, and more unpredictability at every stage. This is something even an artificial intelligence app development company often runs into as projects scale. Without a strong foundation in place, progress slows and momentum fades.

That’s why many teams turn to MLOps to simplify how models are built, tested, deployed, and monitored across complex environments. According to Google Cloud, these practices can cut model launch time by more than half while improving clarity and reliability. When repetitive tasks are handled automatically, teams can focus their energy on what really matters—exploring new ideas, solving real problems, and letting innovation thrive instead of getting stuck in routine work.

Hire Strategically, Not Aggressively

Right now, more companies want people who know AI than there are available. According to LinkedIn’s Future of Work report, positions focused on artificial intelligence rank high on the list of jobs expanding fast across countries.

Moving fast at first might create problems later – skills that do not fit well, people leaving more often.

Instead of rapid mass hiring, businesses should prioritize:

- Engineers with strong fundamentals, not just tool-specific experience

- Candidates who can collaborate across disciplines

- Leaders who can mentor junior team members

Many organizations also partner with an experienced ai & ml development company to supplement internal teams, particularly during periods of rapid growth or specialized development needs. This hybrid approach allows businesses to scale responsibly while maintaining internal knowledge ownership.

Invest in Continuous Learning and Retention

Faster changes in AI mean staying updated matters more than ever. Because skills fade quickly, regular practice keeps teams sharp. Learning happens best when people get clear guidance, room to try things, then reflect on what worked. Some of the strongest groups set aside hours just for testing new ideas. Research papers, tools, and shared notes help spread knowledge across departments. Growth doesn’t come from one big push – it builds slowly through small efforts repeated often.

One way firms keep people around? They train them. IBM found shops that boost worker skills tend to hold onto staff better, plus spark more fresh ideas. When teams grow sharper technically, they often stick closer to the company too. In today’s tight job scene, helping folks learn isn’t just nice – it quietly strengthens trust.

Learning from experienced staff helps teams grow. Sharing ideas inside the group builds stronger skills over time. Working together with colleges adds fresh thinking to daily work.

Embed Ethics and Governance Early

When artificial intelligence grows, its effects on society grow too. Because these systems make choices that affect people, fairness matters more. If personal information is involved, keeping it private turns critical. As machines decide outcomes, understanding how they reach conclusions becomes necessary.

A fresh guide from the National Institute of Standards and Technology aims to support companies building reliable AI tools. When teams grow fast but lack oversight, problems around image, rules, or values might follow.

When rules around data use, how models work, and who takes responsibility are spelled out clearly, expansion doesn’t erode confidence among people. Still, without those lines drawn, progress can quietly undermine belief in systems meant to serve them.

Plan for Long-Term Sustainability

Starting an AI team isn’t a one-time task. The process never really stops. As businesses step into new fields or roll out AI-powered tools, workers must adapt alongside. What happens next depends heavily on how well they respond. Growth shows up where change is handled quietly, steadily.

Something odd happens in firms that actually deliver – team shapes twist without warning. Tech tools swap out, not once, twice, but constantly. Flexibility ends up mattering more than anything else. Size offers no real power in AI work. Months pass, then years, and still, only the ones willing to turn sideways survive. When everything spins quicker each day, old blueprints fade by lunchtime.

Conclusion

What happens when you grow too fast? Without clear direction, adding people changes nothing. Strategy shapes outcomes more than size ever could. Infrastructure must keep pace, quietly doing its job behind every move forward. People improve when learning is built into the rhythm of work. Doing right matters just as much as moving quickly. Intent separates lasting results from empty growth. Governance isn’t paperwork – it’s guardrails for progress. Real problems should pull the effort, not trends. Success sticks around when purpose leads the way.

Facing what comes next means backing real people, clear ways of working, purpose that sticks. Those who do? They stay ahead when smarts build into every part of how things run.

Technology

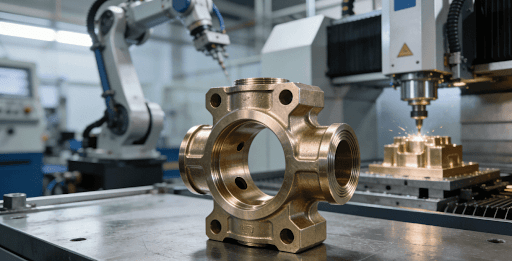

How to Select an Online CNC Machining Service: Avoiding Costly Delays and Ensuring Precision Parts

In today’s fast-paced manufacturing landscape, engineers and procurement managers often face significant challenges when sourcing online CNC machining services. Common issues include slow quotation responses, inconsistent quality, and delivery delays, which can lead to project cost overruns and product development failures. The root cause lies in suppliers’ low digitalization, lack of transparency, and non-standardized processes, making it difficult to identify reliable partners.

This article provides a comprehensive guide to evaluating online CNC machining services by analyzing key selection criteria, instant quote systems, and quality assurance measures. By following these strategies, readers can avoid common pitfalls and ensure rapid delivery of high-precision parts. The following sections will delve into how to identify truly efficient online CNC machining suppliers.

H2: What Are the Essential Criteria for Evaluating an Online CNC Machining Service?

Selecting the right online CNC machining services requires a thorough assessment of core capabilities to avoid delays and ensure precision. This section outlines the essential criteria, emphasizing technical infrastructure, certifications, and transparency.

H3: 1. Technical Infrastructure and Machine Capabilities

A supplier’s technical foundation is critical for handling complex geometries and tight tolerances. Advanced multi-axis CNC machines, such as 5-axis systems, enable single-setup machining, reducing errors and improving efficiency. For instance, equipment capable of achieving tolerances within ±0.005mm is essential for high-stakes industries. Additionally, digital integration through CAD/CAM software ensures seamless toolpath optimization and collision detection, which minimizes scrap rates. Suppliers with modern infrastructure can handle materials ranging from aluminum to engineering plastics, adhering to standards like ASTM for consistency.

H3: 2. Certification and Compliance Standards

Certifications serve as a benchmark for reliability and quality management. ISO 9001:2015 certification, for example, indicates a robust quality management system that focuses on continuous improvement and customer satisfaction. For aerospace applications, AS9100D certification ensures compliance with stringent safety and traceability requirements. Referencing authoritative standards like ASME Y14.5-2018, which defines geometric dimensioning and tolerancing (GD&T), helps suppliers maintain consistent precision. These certifications demonstrate a commitment to standardized processes, reducing the risk of defects and delays.

H3: 3. Transparency and Digital Metrics

Transparency in operations builds trust and facilitates informed decision-making. Key indicators include real-time order tracking and detailed design for manufacturability (DFM) reports. A transparent supplier provides clear communication on project status, potential bottlenecks, and quality checks. Digital platforms that offer live updates and documentation, such as first article inspection (FAI) reports, ensure clients can monitor progress remotely. This level of openness aligns with industry trends toward smart factories and Industry 4.0, enhancing collaboration and reducing misunderstandings.

H2: How Does an Instant Quote System Reflect a Supplier’s Processing Capabilities?

An instant quote system is more than a convenience; it reflects a supplier’s engineering expertise and operational efficiency. This section explores how AI-driven analysis and cost transparency contribute to reliable service.

- AI-Driven DFM Analysis and Cost Breakdown: Modern instant quote platforms use artificial intelligence to analyze CAD files, identifying potential manufacturability issues upfront. This proactive approach includes a detailed cost breakdown based on machine time, material selection, and labor. For example, AI algorithms can suggest design modifications to reduce costs while maintaining functionality, such as optimizing wall thickness for weight reduction. By providing immediate feedback, suppliers demonstrate deep process knowledge, helping clients avoid costly revisions later. This level of detail ensures quotes are accurate and reflective of actual project requirements.

- Efficiency in Quotation Response Time: The speed of quotation delivery indicates a supplier’s digital maturity and workflow optimization. Rapid response times, often within hours, signal streamlined processes and reduced administrative overhead. A delay-free quote system minimizes project startup time, allowing for faster prototyping and production. Suppliers with integrated ERP systems can automate calculations, ensuring consistency and reducing human error. This efficiency is crucial for time-sensitive projects, where quick decisions are needed to meet tight deadlines.

- Avoiding Errors Through Early Detection: An instant quote system serves as an early warning mechanism for design flaws. By highlighting issues like undercut accessibility or tolerance conflicts during the quoting phase, suppliers prevent rework and delays. For instance, a DFM report might flag features that require special tooling, enabling clients to adjust designs before production. This collaborative approach fosters a partnership dynamic, where suppliers act as advisors rather than mere vendors. Ultimately, it leads to smoother project execution and higher client satisfaction.

H2: What Steps Can Suppliers Optimize to Achieve Rapid Delivery in CNC Machining?

Achieving rapid delivery in CNC machining hinges on optimizing production steps, from design review to final inspection. This section details key strategies, including parallel engineering and smart scheduling.

H3: 1. Parallel Engineering and Concurrent Processes

Suppliers can accelerate timelines by implementing parallel engineering, where design, programming, and material procurement occur simultaneously. For example, while CAD models are being optimized, material orders are placed based on projected needs. This approach reduces idle time and compresses overall project duration. In cases like prototyping, it can cut lead times by up to 35%, ensuring parts are delivered in days rather than weeks. Concurrent workflows require strong coordination but yield significant efficiency gains.

H3: 2. Intelligent Scheduling and Resource Allocation

Advanced scheduling systems use algorithms to prioritize tasks based on urgency and resource availability. Smart scheduling minimizes machine downtime and balances workloads across multiple projects. For instance, a supplier might group similar jobs to reduce setup changes, optimizing throughput. Real-time monitoring of machine status allows for dynamic adjustments, preventing bottlenecks. This level of optimization is often supported by certifications like IATF 16949, which emphasize process control in automotive and similar industries.

H3: 3. Streamlined Post-Processing and Logistics

Post-processing steps, such as surface finishing and assembly, can be streamlined through automation and just-in-time practices. Automated finishing equipment reduces manual handling, while integrated logistics partners ensure fast shipping. Suppliers with in-house post-processing capabilities avoid external delays, providing end-to-end control. For example, a dedicated packaging and shipping unit can guarantee that parts are dispatched immediately after quality checks, meeting tight delivery windows.

H2: How to Ensure Quality Control in Online CNC Machining Collaborations?

Quality control is paramount in remote collaborations, where physical oversight is limited. This section explains methods like digital documentation and real-time monitoring to maintain standards.

- Digital Documentation and FAI Reports: Comprehensive digital records, including first article inspection (FAI) reports, provide verifiable proof of compliance. These documents detail dimensional checks against CAD models, ensuring parts meet specifications. Suppliers adhering to standards like ISO 9001 maintain detailed logs for traceability, which is critical for regulated industries. Clients can review these reports online, facilitating transparent communication and reducing the need for on-site visits.

- Real-Time Monitoring and Closed-Loop Systems: Real-time monitoring using sensors and IoT devices allows suppliers to track machining parameters like tool wear and temperature. Closed-loop systems adjust processes based on feedback, maintaining tolerances within ±0.01mm. For example, on-machine probes can perform in-process inspections, catching deviations early. This proactive approach minimizes scrap and rework, ensuring consistent quality throughout production.

- Collaborative Engineering and Continuous Feedback: Quality is enhanced through collaborative engineering, where clients and suppliers work together on design optimizations. Regular feedback loops, supported by digital platforms, enable quick iterations. Suppliers that encourage client input during the DFM phase build stronger relationships and improve outcomes. This partnership model aligns with quality management principles, fostering a culture of continuous improvement.

H2: What Are the Key Differences Between Online CNC Prototyping and Mass Production?

Understanding the distinctions between prototyping and mass production helps in selecting the right service approach. This section compares speed, cost, and flexibility factors.

H3: 1. Speed vs. Cost Optimization Strategies

Prototyping prioritizes speed, often using rapid turnaround times of 1-3 days to validate designs. In contrast, mass production focuses on cost efficiency through economies of scale, with longer lead times optimized for volume. Suppliers may use different machine setups — e.g., high-speed machining for prototypes versus dedicated lines for production. This distinction ensures that projects transition smoothly from concept to bulk manufacturing without compromises.

H3: 2. Material and Process Flexibility

Prototyping allows for greater material experimentation, with suppliers offering a wide range of options for testing. In mass production, material choices are standardized to reduce costs and ensure consistency. Processes like tooling design are more rigid in production to maintain uniformity, whereas prototypes might employ adaptive methods. This flexibility in prototyping supports innovation, while production emphasizes reliability.

H3: 3. Scalability and Supply Chain Integration

Scalability is key when moving from prototyping to production. Suppliers with integrated supply chains can manage material sourcing and inventory for large runs, avoiding disruptions. For instance, a manufacturer with IATF 16949 certification can handle automotive volume demands seamlessly. This capability ensures that quality and delivery timelines are maintained as orders scale up.

H2: How Can Companies Leverage Certifications like AS9100D for Aerospace Projects?

For high-risk industries like aerospace, certifications such as AS9100D are crucial for ensuring compliance and reliability. This section explains their application in complex part manufacturing.

H3: 1. Rigorous Process Controls and Traceability

AS9100D mandates strict process controls, including detailed documentation and audit trails. Every step, from material sourcing to final inspection, is recorded for full traceability. This is vital for aerospace components, where failures can have severe consequences. Suppliers with this certification demonstrate an ability to handle critical tolerances and complex geometries under regulated conditions.

H3: 2. Risk Management and Supplier Validation

The certification emphasizes risk management, requiring suppliers to identify and mitigate potential issues proactively. For example, advanced FMEA (Failure Mode and Effects Analysis) is used to anticipate problems in machining processes. Additionally, supplier validation ensures that all partners meet the same high standards, creating a secure supply chain. This comprehensive approach reduces uncertainties in projects.

H3: 3. Case Example: Practical Application in Aerospace Manufacturing

In a practical case, one manufacturer utilizes AS9100D to manage aerospace projects, ensuring parts like turbine blades meet exacting standards. By integrating real-time monitoring and closed-loop systems, they achieve consistency in high-precision components. This example highlights how certifications translate into tangible benefits, such as reduced rejection rates and enhanced client confidence..

H2: Conclusion

Selecting an CNC machining services requires a methodical approach based on key criteria like technical capabilities, certifications, and transparency. By leveraging instant quote systems, optimizing delivery steps, and ensuring robust quality control, businesses can avoid delays and secure precision parts. This guide empowers readers to make informed decisions, fostering successful collaborations in a digital manufacturing era.

H2: FAQs

Q1: What is the typical lead time for online CNC machining services?

A: Lead times vary based on complexity, but reliable suppliers with ISO 9001 certification can deliver prototypes in 1-3 days and production runs within weeks. Factors like design optimization and material availability influence timelines, ensuring projects stay on schedule without compromising quality.

Q2: How accurate are the quotes provided by online CNC platforms?

A: Quotes are highly accurate when based on detailed CAD files, as AI-driven systems analyze machine time and materials. However, final costs may adjust after DFM review to address manufacturability issues, ensuring transparency and cost-effectiveness.

Q3: What materials are commonly available for CNC machining?

A: Common materials include aluminum, stainless steel, titanium, and engineering plastics, with over 100 options available. Suppliers often provide guidance on selection based on mechanical properties, corrosion resistance, and cost, adhering to standards like ASTM for consistency.

Q4: Can online CNC services handle complex geometries and tight tolerances?

A: Yes, advanced services utilize multi-axis CNC machines to achieve tolerances as tight as ±0.005mm. Through real-time monitoring and GD&T standards, they ensure complex designs meet specifications, supported by certifications like AS9100D for high-risk industries.

Q5: How is intellectual property protected when using online CNC services?

A: Reputable suppliers implement NDAs, encrypted data transmission, and secure storage to safeguard designs. Post-project, data can be erased upon request, aligning with ethical practices and building trust through compliance with international standards.

H3: Author Bio

The author is a precision manufacturing expert at LS Manufacturing, a company that helps engineers and researchers solve complex part challenges in aerospace, medical, and automotive industries. With certifications such as ISO 9001, IATF 16949, and AS9100D, the team ensures high-quality solutions through advanced technologies. For more insights, visit their service page for a free, no-obligation project review and DFM analysis.

Technology

Reducing Defect Rates by 50% A Guide to Precision Manufacturing Techniques for Bronze CNC Machining

In high-precision manufacturing, CNC Machining Bronze is essential for creating durable, wear-resistant components, yet it poses significant challenges like rapid tool wear and part deformation due to the material’s low thermal conductivity and toughness .

These issues often stem from reliance on traditional, experience-based parameter settings, leading to higher scrap rates and costs . A modern solution integrates advanced material applications and automated production methods, supported by precision manufacturing technology, to enable data-driven optimization for enhanced accuracy and efficiency .

H2: What are the key technologies in bronze CNC machining?

The success of bronze alloy machining hinges on the synergistic application of several core technologies that ensure process control and final part quality. These technologies form the foundation of efficient and accurate metal CNC machining for bronze components.

H3: Intelligent Programming and Real-Time Monitoring

Effective CNC programming and process control are paramount. For CNC Machining Bronze, programmers must optimize tool paths to avoid sharp directional changes and excessive cutting depths, minimizing fluctuations in cutting force and heat accumulation. Modern CNC systems incorporate Precision Manufacturing Technology through real-time monitoring. Sensors track critical parameters like cutting force, vibration, and temperature, allowing the system to make adaptive adjustments, such as automatically fine-tuning the feed rate upon detecting abnormal vibration to prevent tool chatter. This dynamic feedback loop significantly extends tool life and ensures batch-to-batch consistency .

H3: Material Science and Toolpath Optimization

A deep understanding of the material is indispensable for successful machining. The specific properties of bronze alloys directly influence their machinability and require tailored approaches.

l Phosphorus Bronze (C54400) Considerations

For example, the microstructure of phosphor bronze (e.g., C54400) is influenced by its phosphorus content, which affects its work-hardening tendency. Optimizing cutting speeds (typically recommended at low to medium ranges) and using sharp, positive rake angle tools can effectively minimize the work-hardened layer and control heat generation .

l Data-Driven Parameter Selection

Successful machining requires optimizing parameters based on alloy characteristics. As highlighted in the CNC Machining Bronze Guide, this involves selecting appropriate cutting speeds, feed rates, and tool geometries to mitigate bronze’s specific challenges. This data-driven approach is crucial for achieving both efficiency and precision in production .

H2: How to improve bronze processing efficiency through automated production methods?

In the pursuit of scalability and high consistency, Automated Production Methods have become essential for boosting efficiency and reducing human error in bronze machining. Within an automated framework, robots are deployed for repetitive tasks such as loading/unloading and clamping workpieces. This not only frees operators for higher-value tasks but also enables lights-out manufacturing. For batch production of Bronze Machined Parts, automated lines ensure every workpiece is clamped with identical position and force, fundamentally eliminating datum errors caused by manual intervention .

Advanced automation systems incorporate intelligent feedback loops. In-process measurement probes can automatically check critical dimensions during or between machining operations, feeding data back to the CNC controller for compensatory adjustments. This automated closed-loop control of cutting forces can effectively prevent part deformation caused by stress relief or thermal input, potentially reducing related scrap rates significantly. When combined with rigorous quality management systems like ISO 9001, professional CNC machining services can offer highly reliable quality assurance. It is important to note the automation differences between bronze and brass.

While both are copper alloys, CNC machine brass is generally more amenable to high-speed automation due to its excellent chip-breaking properties. When machining bronze, automated systems must place greater emphasis on precise coolant delivery and flexible parameter adjustment to cope with its higher viscosity and poorer thermal conductivity, underscoring the need for tailored automation solutions .

H2: How do advanced material applications optimize bronze part performance?

Moving beyond conventional machining, innovation at the material level is a frontier for enhancing the end-use performance of bronze components. Advanced Material Applications encompass the entire workflow from alloy selection to post-processing. Selecting the appropriate bronze alloy for the service environment is the first step. For instance, aluminum bronze (e.g., C95400), known for its high strength and exceptional corrosion resistance, is particularly suitable for wear parts in marine engineering or heavy industry. Understanding these bronze alloy machining characteristics is the cornerstone of designing high-performance custom bronze parts that meet specific operational demands .

Heat treatment is a key process for unlocking a material’s potential. For certain bronze alloys, solution treatment and aging hardening can significantly increase hardness and strength. This controlled thermal process optimizes the material’s microstructure, granting higher wear resistance and dimensional stability while maintaining sufficient toughness. Furthermore, to enhance surface performance, various coating technologies like Physical Vapor Deposition (PVD) can be applied. This combination of Precision Manufacturing Technology with material science can multiply the service life of parts in harsh environments .

H2: What role do innovative prototyping solutions play in bronze machining?

In the new product development phase, Innovative Prototyping Solutions are critical for design validation, risk reduction, and accelerating time-to-market, especially for bronze parts with complex machining requirements. These solutions allow for thorough testing and refinement before committing to full-scale production.

H3: Rapid Iteration and Risk Mitigation

Innovative Prototyping Solutions are crucial for validating designs and mitigating risks before full-scale production. Traditional prototype methods are often costly and slow.

l Hybrid Manufacturing for Functional Prototypes

Combining 3D printing for rapid mold creation with precision CNC machining enables the fast fabrication of functional Bronze Machined Parts. This allows designers to physically test assemblability, functionality, and performance, identifying flaws early.

l Reducing Production Risks

Creating physical prototypes enables comprehensive durability and environmental simulation testing. This “test-before-production” model significantly reduces technical and market risks. For reliable services, explore professional CNC machining solutions.

H3: Enabling Complex Designs and Quality Assurance

These solutions unlock advanced part geometries while ensuring high standards. Modern designs frequently feature internal channels and complex surfaces. Technologies like 5-axis simultaneous metal CNC machining can produce these intricate structures in a single, high-precision setup. Furthermore, providers with certifications like AS9100D adhere to strict quality controls from the start, ensuring even complex custom bronze parts meet the highest reliability standards.

H2: How to integrate precision manufacturing technology to achieve zero error in bronze machining?

Achieving “zero error” in bronze machining does not rely on a single technology but on the systematic integration and closed-loop management of multiple Precision Manufacturing Technology. The core equipment of modern high-precision CNC machining services is the 5-axis simultaneous CNC machine tool. It allows the tool to approach the workpiece from any angle, enabling the complete machining of all surfaces of a complex part in a single setup. This eliminates cumulative errors caused by multiple re-clamping, which is fundamental for ensuring geometric tolerances for bronze alloy machining parts .

The integration of “measurement-machining” is a hallmark of precision manufacturing. On-machine probing systems can automatically measure workpiece dimensions during or between operations and compare them with the digital model (CAD). If minor deviations caused by tool wear or thermal deformation are detected, the system immediately generates compensation values, instructing the tool to make corrections in subsequent operations. This creates a real-time quality closed loop, ensuring dimensional tolerances are stably controlled within tight limits.

Ultimate lean production is built on data. By collecting and analyzing cutting parameters, tool life, and quality inspection data from each machining operation, the process database can be continuously optimized. This data-driven decision-making model can scientifically determine the optimal processing window for each bronze material and tool .

H2:Conclusion

To overcome bronze CNC machining challenges, a systematic approach integrating precision manufacturing technology, automated production methods, and advanced material applications is essential. This holistic strategy minimizes tool wear and part deformation, significantly reducing costs and enhancing ROI. Partnering with an experienced provider ensures optimal results.

H2:Author Biography

This article was written by an expert in the manufacturing field. The team at JS Precision has years of experience in precision machining and is committed to providing reliable metal component solutions through technological innovation and rigorous processes.

H2:FAQs

Q1: What are the main challenges of bronze CNC machining?

A1: Tool wear and thermal deformation are common problems due to bronze’s high toughness and poor thermal conductivity. These can be mitigated by optimizing cutting speed and coolant application to ensure dimensional stability.

Q2: How to select a bronze alloy for custom parts?

A2: Material selection should be based on application requirements. For example, phosphor bronze is often used for bearings, while aluminum bronze offers excellent corrosion resistance. Material properties influence machining parameters and should be chosen with reference to professional guides.

Q3: How much cost can automated production methods reduce?

A3: Automation can reduce human error and improve efficiency by 20-30%, though initial investment needs evaluation. Long-term, the reduction in scrap rate can save over 15% of total costs.

Q4: Are innovative prototyping solutions suitable for low-volume production?

A4: Yes, rapid prototyping allows for design testing, reducing errors in mass production. Combined with CNC machining, low-volume orders can achieve high precision with controllable costs.

Q5: How does precision manufacturing technology ensure part tolerances?

A5: Through real-time monitoring and adaptive control, technologies like 5-axis CNC can maintain tight tolerances. A strict quality inspection process is critical.

Technology

Pigeimmo: Navigating the Future of Real Estate with Trends and Insights

Pigeimmo is a modern concept in real estate that combines behavioral intelligence, real-time data, and predictive analytics to help investors, agents, and developers make more informed decisions. The word itself is a blend of “pige” (from “pige immobilière,” a French term for real estate prospecting) and “immo” (short for immobilier, meaning real estate).

What Is Pigeimmo?

Pigeimmo is a modern concept in real estate that combines behavioral intelligence, real-time data, and predictive analytics to help investors, agents, and developers make more informed decisions.

Unlike traditional tools that rely heavily on historical pricing data or static property listings, Pigeimmo places emphasis on how people move, behave, and interact with urban spaces.

Why Pigeimmo Matters

-

Real-Time Insight

Pigeimmo collects live data from various sources — mobile devices, public transport flows, Wi-Fi and Bluetooth signals, IoT sensors, and even heat maps — to understand how people use different parts of a city. -

Behavioral Intelligence

By analyzing behavioral patterns (like how long people linger in an area, or how often they return), it can identify which locations have genuine demand or potential. -

Predictive Analytics

Using machine learning, Pigeimmo predicts future hotspots — areas likely to become more valuable or active — and helps in setting dynamic strategies (for pricing, development, or leasing). -

Efficient Lead Generation

For real estate agents, Pigeimmo can act like a lead-generation engine, alerting them to new, motivated sellers or properties before they hit mainstream platforms. -

Sustainable and Smart Development

In some real estate developments, Pigeimmo isn’t just about data — it’s also tied with green design. Projects associated with the concept may include vertical gardens, smart energy systems, and IoT to make buildings more efficient and eco-friendly. -

Community-Driven Urban Planning

City planners and developers can use Pigeimmo insights to plan for how public spaces will be used, optimize foot traffic, and design for people’s actual habits — not just for theoretical models.

Key Features of Pigeimmo

-

Smart Lead Prospecting: Monitors multiple listing sources and sends real-time alerts when new properties matching your criteria appear.

-

Hyper-Targeted Filters: Allows users to filter by city, budget, size, property type, etc., so they only get relevant leads.

-

Direct Seller Contact: Automatically extracts seller contact details (when available) so agents can reach out quickly.

-

Predictive Modeling: Uses past and current behavioral data to forecast which areas are likely to grow or decline.pVirtual Tours & AR: Some versions incorporate virtual reality or AR tools to let users explore properties remotely.

-

Secure Transactions: Emphasis on privacy, data anonymization, and secure communication for deals.

Benefits by Stakeholder

-

For Agents / Brokers: Faster, higher-quality lead generation; reduced time chasing unqualified leads; better conversion because they reach sellers early.

-

For Investors: Ability to identify emerging investment zones before they become expensive; make data-driven buy or hold decisions.

-

For Developers: Insight into how urban areas are used; optimize design based on real human flows; create mixed-use or green projects smartly.

-

For City Planners: Use behavioral data to guide urban design, improve public spaces, and direct infrastructure investments.

-

For Homebuyers: More transparency, better insight into how an area is used, and potentially lower costs through efficient building systems.

Challenges & Risks

-

Privacy and Ethics: Collecting behavioral data raises questions about surveillance. Even if anonymized, there needs to be transparency and ethical safeguards.

-

Data Bias: Areas with fewer sensors or lower digital connectivity may be underrepresented, skewing insights.

-

Over-Reliance on Prediction: Predictive models are powerful but not foolproof; unexpected social, economic, or political changes can invalidate forecasts.

-

High Upfront Costs: Implementing smart building systems and green infrastructure costs more initially, even if it saves money long-term.

-

Regulatory and Compliance Hurdles: Using behavioral data, especially for urban planning or pricing, might face regulatory constraints or public resistance.

Future Outlook

-

Participatory Pigeimmo: In some visions, Pigeimmo could evolve into a participatory platform where citizens contribute data consciously — not just passively — influencing how their neighborhoods develop.

-

Blockchain Integration: Smart contracts and blockchain could make transactions more transparent and secure, especially for co-ownership or fractional investment models.

-

Smart-City Connectivity: Buildings using Pigeimmo intelligence might communicate with city infrastructure (energy grids, transport) to optimize resource use.

-

Wider Adoption: As more agents, developers, and planners recognize the value of behavioral data, Pigeimmo-style intelligence could become a mainstream part of real estate strategy.

Conclusion

Pigeimmo represents a paradigm shift in real estate. Rather than just analyzing what has happened (prices, comps, historical data), it focuses on what is happening now and what is likely to happen next, by understanding how people physically use urban space. This insight can lead to smarter investments, more efficient designs, and more responsive urban planning.

For real estate professionals, investors, and city planners, Pigeimmo offers a powerful tool — but it also brings ethical and technical challenges that must be handled carefully. As technology and data collection evolve, so too will the role of behavioral intelligence in shaping our cities and our property markets.

-

food3 months ago

food3 months agoCalamariere: How to Perfectly Prepare at Home

-

Technology3 months ago

Technology3 months agoYourAssistantLive com: The Future of Smart Digital Assistance

-

Blog3 months ago

Blog3 months agoBaddi Hub: An Emerging Industrial and Business Hotspot

-

Blog3 months ago

Blog3 months agoSimpcit6: Redefining Simplicity in a Complex World

-

Crypto3 months ago

Crypto3 months agoCrypto30x.com vs Other Crypto Sites – Best Bitcoin Tools?

-

Technology2 months ago

Technology2 months agoVoomixi com: The Digital Platform Redefining Online Interaction

-

Health2 months ago

Health2 months agoNerovet AI Dentistry: Enhancing Patient Experience and Treatment Outcomes Dental Care

-

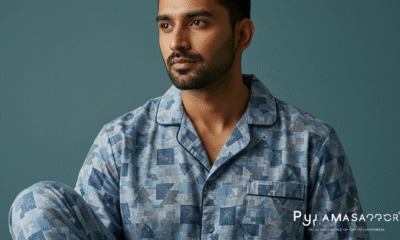

Lifestyle3 months ago

Lifestyle3 months agoPyjamaspapper: The Ultimate Blend of Comfort and Style in Sleepwear